MATTHIESEN LIVE BOTTOM BINS

The Matthiesen Live Bottom Bin is a very versatile piece of equipment when you need to store product between harvests. The live bottom bin advances the product forward using a flor and front rake to keep product moving onto the screw conveyor to your bagging lines. Optional equipment can be added to the live bottom bin, such as slingers of leveling screws, to make your operation highly efficient.

Features & Benefits

- Bins available in true 5, 10, 15, 20, 30 and 40 ton capacity

- UHMW wall and floor

- All other contact surfaces are stainless steel

- Separate drive for floor, rake and screw

- Drives are direct coupled, which eliminates chain and sprocket

- UL certified control panel

- Rugged galvanized frame standard (stainless steel available)

- Legs included (any size up to 3′ standard)

- Ball bearings

- Easy to assemble and maintain

- 14 ton max discharge rate per hour

- Discharge conveyor direction can be changed in the field

- 2 Lexan vertical rake viewing windows

- Proximity sensor for filling hopper

- Electrical 230/3/60 or 460/3/60

Options

- Custom configurations available

- Spreader to disperse product evenly

- Floor advancement controls (allows for first in, first out)

- Bin full switch

- Drain pans

- Top cover

- Additional Lexan viewing panels

- Remote control panel

- Other electrical options available

- Access door

- Leveling screw

Dimensions

Bin is used for temporary storage of product while awaiting utilization. When activated, the floor and front wall rake keep product moving to a bin mounted conveyor transporting, product to the next process station.

| 5 Ton with Discharge Screw | 10 Ton with Discharge Screw | 15 Ton with Discharge Screw | 20 Ton with Discharge Screw | 30 Ton with Discharge Screw | |

| Length | 9’6″ | 15′ | 20’2″ | 20’2″ | 23’5″ |

| Width | 9’5″ | 9’5″ | 9’5″ | 11’5″ | 11’5″ |

| Height | 12′ | 12′ | 12′ | 12′ | 14′ |

| Weight | 4,400 LBS | 5,400 LBS | 6,400 LBS | 7,400 LBS | 8,400 LBS |

BELT CONVEYOR SYSTEMS

The Matthiesen Belt Conveyor Systems is flexible and can be integrated in the most extreme conditions and applications with dependability to reduce maintenance costs.

Features & Benefits

- 4″ wheel casters

- Rough top belting with stainless steel lacing

- Belt lengths 3′-12′, width 10″

- Electrical 115/1/60

- Motor 3′ to 14′ length with standard FPM 60′-62′ per minute

- Amp draw 4.6 @ 115 Volt or 2.3 @ 230 Volt

- Adjustable legs 12″-40″

Options

- White smooth top or crescent top FDA approved belting available

- Cleated belt available

- Side rails available in any height and length

- Reversible

- Other belt widths available

- TEFC washdown motors available in 1/4 HP or 1/2 HP

Dimensions

| Size: | 36-144in x 10in x 12-40in (LxWxH) |

| Weight: | 200 LBS |

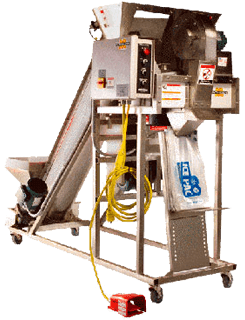

VLS SERIES BAGGER

The Matthiesen VLS Bagger is a highly functional piece of equipment with automatic or manual settings, this bagger is simple and productive whether you are bagging ice, coal, rice, beans, corn or many other products. Load the bottom hopper and the product is conveyed to the top hopper, which has an optional lower and upper limit switch, fills the volumetric drum in increments of 5 to 25 pounds. Depending on the type of product being bagged, this equipment is capable of filling up to 40 bags per minute.

Features & Benefits

- Galvanized with stainless inner and outer drum, downspout and bag opener

- Adjustable speed 20-47 bags / minute

- Totally enclosed fan cooled (TEFC) motor

- Screw conveyor

- Volumetric filler

- Top hopper full (Proximity Switches)

- Automatic bag opener (blower)

- Manual stop, restart foot-pedal

- 5″ Casters for mobility

- PVC electrical box

Electrical: 120/1/60

Amp Draw: 30 am draw, other electrical available

Lower Hopper to Floor: 30″

Lower Hopper Size: 24″ x 19″

Caster Height: 5″

Bag Specifications:

- 3/4″ wicket holes with 1/4″ land area with 1/8″ slit at top of bag

- 1-1/2″ crimped lip

- 6″ reverse wickets

- Bottom gusset

Model Capacity

| Models | |

| VLS35 | Smallest bag filled is 3 lbs |

| VLS510 | Smallest bag filled is 5 lbs |

| VLS815 | Smallest bag filled is 8 lbs |

| VLS2025 | Smallest bag filled is 20 lbs |

Options

- Spare parts kit

- Bag closer (ring bag or heat seal)

- Slapper and Wiggler

- Caster lock kit

- Wash down motors

- Corrosion resistant parts either stainless steel, aluminum or high density polyethylene

- Poly lined hopper upper and lower hopper

- Low level proximity switch

- Spill return screw

Dimensions

| Uncrated | Crated | |

| Length | 93″ | 97″ |

| Width | 36″ | 40″ |

| Height | 72-3/4″ (VLS35), 76-1/2″ (VLS150), 79-1/2″ (VLS815 & VLS2025) | 76-3/4″ (VLS35), 80-1/2″ (VLS150), 83-1/2″ (VLS815 & VLS2025) |

| Weight | 850 LBS | 950 LBS |

MAGIC FINGER SYSTEM

The Matthiesen Magic Finger System is a fully automatic bagger allowing 5 to 10 pound bags to be filled and closed automatically. Product is moved from the hopper to the volumetric drum then dropped in a pre-positioned bag. The Magic Finger pulls the bag with assistance from the bag conveyor to the optional bag closing unit.

Features & Benefits

- Corrosion resistant parts either stainless steel, aluminum or high density polyethylene

- Electrical: 120/1/60, 20 amp draw

- Volumetric filler

- UL certified control panel

- Hamer 125 mount

- Completely adjustable for multiple bag size

- Fully automatic

- 5-10 lb dumps, capacity 5-10 lb bags

- Low level ice detection (Proximity) supplied with high level proximity switch, normally closed

- Automatic bag opener (blower)

- UHMW lined hopper

- Variable speed control

- Sure fall ice drop

- 5″ casters for mobility

- Accepts bag closer for Hamer 125, heat seal, or Kwik Lok

- Lexan viewing window

- Adjustable conveyor height

- Take away conveyor

- Remote production controls

Bag Specifications (required): 5-15lb bags

- 3/4″ wicket holes

- 1/4″ land areas with 1/8″ slit at top of bag

- 1-1/2″ crimped lower-lip

- 6″ reverse wickets

- Bottom gusset

- Minimum width of 10″ on 5-15 lb bags

- Minimum width of 14″ on 18-25 lb bags

Capacity Examples

| Models | Bags | Speed |

| MFHSB 510 | 5-10LB Bags | 40+ bags / minute |

| MFHSB 815 | 8-15LB Bags | 35+ bags / minute |

| MFHSB 20 | 18-25LB Bags | 16+ bags / minute |

Options

- Bag closer – Hamer 125, heat seal, or Kwik Lok

- Casters with locks

- Washdown motors

Dimensions

| Uncrated | Crated | |

| Length | 77″ | 82″ |

| Width | 44″ | 49″ |

| Height | 80″ | 85″ |

| Weight | 985 LBS | 1,200 LBS |

BUCKET ELEVATOR

The Matthiesen Bucket Elevator is food grade approved and the perfect piece of equipment if you are looking for a solution to conveying your product with limited floor space. The Bucket Elevator can be customized to fit your exact space requirements.

Features & Benefits

- Capacity

- 24″ wide moves 7 tons/hour

- 36″ wide moves 13 tons/hour

- Corrosion resistant parts either stainless steel or high density polyethylene

- Acetal polyoxymthylene bucket belt

- Washdown motor and gear reducer

- Stainless steel ball bearings

- Food Grade approved materials

- Effective water removal

- Low horsepower requirement

- Increased safety (compared to other conveyor systems)

- Easily maintainable components

- Versatile configurations

- Moves a wide variety of product

Options

- Custom size hoppers

- Custom configurations

Dimensions

| Size: | 40in x 25in x 58in (LxWxH) |

| Weight: | varies with custom sizes |

ADDRESS

401 N. Mills Ave Ste B,

Orlando, FL 32803

United States

PHONE CONTACT NUMBER

+1 321 240 5124

+58 414 598 0407

E-MAIL CONTACT

dicalmiami@gmail.com